Over the last two decades, 3D printing has emerged as one of the most transformative technologies of our time. No longer confined to rapid prototyping in labs, it has become a core driver of innovation, enabling scientists, engineers, product managers, startups, and artists to transform ideas into tangible products with remarkable speed. From aerospace components to personalized medical devices, 3D printing is fundamentally changing the way we design, produce, and iterate.

A Brief History: From Concept to Revolution

The origins of 3D printing trace back to 1984, when engineer Chuck Hull invented stereolithography—the first process that could build objects layer by layer using photopolymers. His company, 3D Systems, pioneered early applications, but for years, the technology remained expensive and limited to industrial use.

The true explosion of popularity came in the 2000s, when open-source projects such as RepRap (Replicating Rapid Prototyper) made 3D printer designs freely available. This openness not only drove down costs but also sparked a global community of innovators, hobbyists, and researchers. What was once a high-cost industrial tool became an accessible, personal technology—fueling today’s widespread adoption.

From Prototype to Production: A Paradigm Shift

Traditional manufacturing pipelines are often constrained by tooling costs, long lead times, and centralized production facilities. 3D printing, by contrast, allows rapid iteration and decentralized production. According to industry analysts, companies using additive manufacturing can reduce product development cycles by 50–70%, accelerating innovation and lowering financial risk. For startups and research labs, this is not just a convenience—it’s a strategic advantage.

Democratizing Innovation

Perhaps the most profound impact of 3D printing lies in its democratization of manufacturing. Ordinary individuals can now design and fabricate complex objects that would have previously required expensive industrial equipment. The convergence of accessible software, affordable printers, and open-source design libraries has fostered a global ecosystem of innovators, where the boundaries between designer, engineer, and manufacturer are increasingly blurred.

Sustainability and Recycling

From an environmental perspective, additive manufacturing has both opportunities and challenges:

- Material Efficiency: Unlike subtractive methods (milling, cutting, injection molding), 3D printing generates minimal waste.

- Recycled and Bio-Based Filaments: Many modern 3D printers can use recycled plastics, PLA (polylactic acid), or other bio-based materials, contributing to circular material flows. Startups are now developing filaments from post-consumer plastics, ocean waste, and agricultural byproducts.

- Repair at Home: For individuals, a 3D printer is not only a tool for creation but also for extending the life of products. Instead of discarding a household item, users can design and print a replacement part—reducing waste and saving costs. This ability to repair instead of replace makes 3D printing a uniquely sustainable technology at the consumer level.

- Sustainability Limits: Energy consumption can be high for industrial-scale printers, and not all recycled filaments meet structural or quality standards for critical applications. Nevertheless, as technology improves, additive manufacturing has the potential to be a more sustainable alternative to traditional mass production.

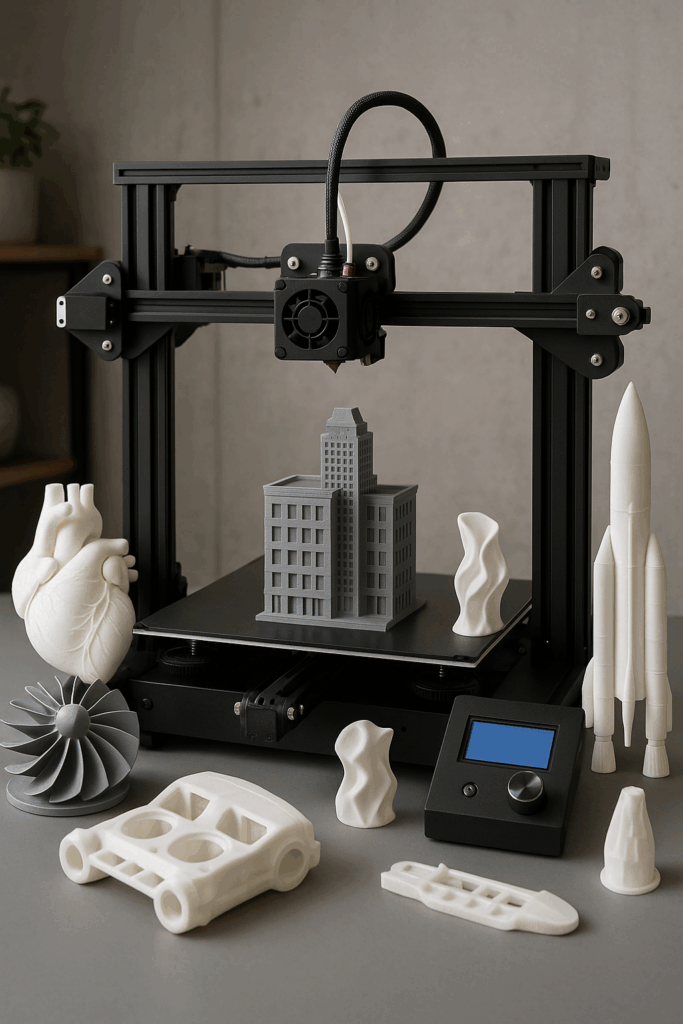

Applications Across Industries

- Healthcare: Patient-specific prosthetics, dental implants, and even experimental bio-printed tissues are transforming medical treatment.

- Aerospace & Automotive: Lightweight, high-strength components reduce fuel consumption and improve efficiency.

- Architecture & Construction: 3D-printed structures offer reduced material waste, lower costs, and unprecedented design flexibility.

- Art & Design: Artists and designers explore complex geometries and bespoke creations impossible through conventional means.

- Space Exploration: Agencies like NASA are leveraging 3D printing for on-demand fabrication of tools and components in space, reducing supply chain dependence.

Expert Insight

Leading experts in additive manufacturing note that 3D printing is not just a technology—it is a methodology. It encourages iterative experimentation, cross-disciplinary collaboration, and localized production. By integrating AI-driven design optimization, multi-material printing, and advanced composites, researchers envision a future where production becomes as flexible and adaptive as digital software.

Looking Forward

3D printing remains at the frontier of technological innovation. With advances in speed, multi-material capabilities, and sustainability, it is poised to reshape manufacturing, reduce environmental impact, and empower a new generation of creators. Its potential is vast: distributed factories, on-demand production, and fully sustainable materials may redefine how we build the world around us.

Conclusion

3D printing exemplifies how technology can transform imagination into reality. From Chuck Hull’s first experiment in the 1980s to today’s open-source-driven innovation wave, it has grown into a force that empowers individuals and industries alike. For scientists, entrepreneurs, and creative thinkers, it represents a tool of unprecedented power—enabling faster, more sustainable, and more innovative pathways to invention.

This blog post was written with the assistance of ChatGPT, based on ideas and insights from Edgar Khachatryan.